we don't accept imitations and neither should you. This is why we guarantee our melee diamond stock is 100% natural. Why not put us to the test? We always do.

We also operate a blanket screening of every single sustainable diamond, before it leaves our hands, to ensure authenticity. Screening for stones between 1mm and 3.8mm takes place at our facility, where we use De Beers developed AMSII or HRD-developed M-Screen 4.0 technology. Any diamonds that are smaller or larger than this are sent to respected independent laboratories, such as Forever mark's IIDGR or the International Gemological Institute (IGI) for testing.

We offer four categories of sustainable diamonds

loupe clean, fine VS,

white SI and commercial SI

Our sizes range from

0.90 mm to 2.70 mm

(in 0.05mm

increments)

Color gradings

run from D through to G

The brilliance of a diamond is ultimately in the hands of the cutter. The temptation to cut a diamond for heavier weight rather than for the most beautiful shape, proportion, and brilliance is the dilemma facing all manufacturers.

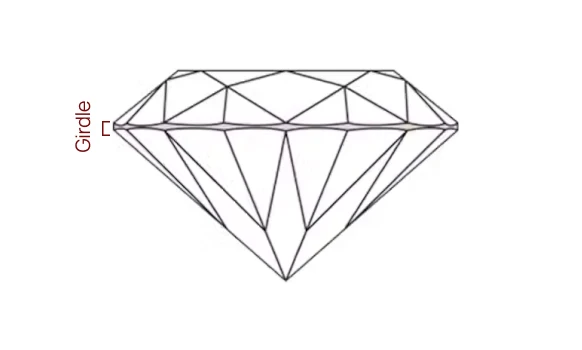

The girdle of a diamond is the thin perimeter of a diamond, dividing the crown above from the pavilion below. A diamond girdle can be rough, polished, or faceted. With a certified stone, you will be able to see the inscription on the girdle with a loupe or microscope.

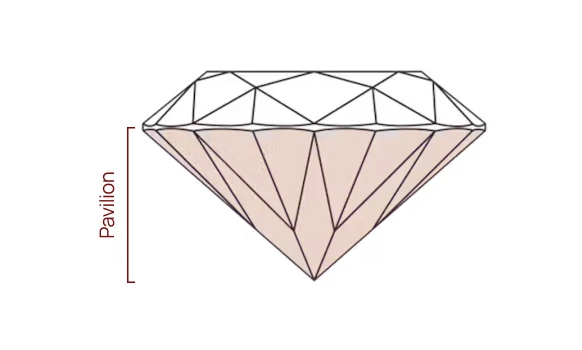

In a diamond, the pavilion is the space below the girdle. This part of the diamond's anatomy is frequently the noticeable "V" shape of the base of the diamond. The pavilion is the part of the stone that reflects light back down through the crown at the viewer

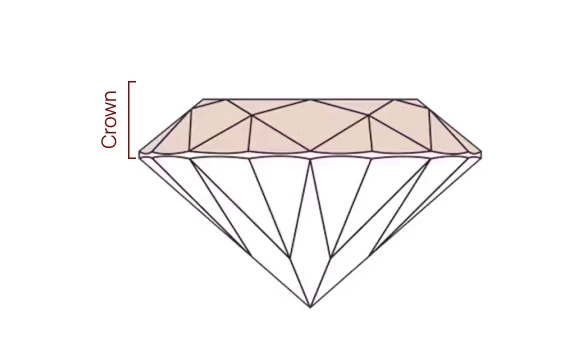

Crown The crown is the top of the diamond which includes a large flat area, called the table, and a number of facets. The main function of the crown is to disperse the light that enters the diamond into white light, which gives the diamond its brilliance.

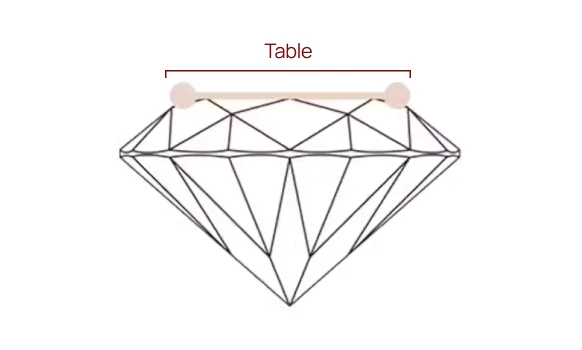

Table A diamond's table is the flat facet in its surface - the large, flat surface facet that you can see when you look at the diamond from above. As the largest facet on the diamond, the table plays a major role in determining how brilliant the diamond is.

1

In the skilled hands of a diamond expert, the rough stone undergoes meticulous mapping.

2

A high-powered laser is used to carve away each inclusion ensuring that the stone retains as much of its weight as possible.

3

The craftsmen carefully shape the diamond into an oval cut a classic shape, with its elongated curves, enhances the stone's inherent beauty.

4

A process where the facets were roughly cut into the stone creating a base upon which the final polish would work its magic.

5

In the skilled hands of a master diamond cutter, the oval diamond received its final, exquisite polish until it gleamed with a radiant, mirror-like finish.